Plants

Modular systems for API, HPAPI and intermediates synthesis

The synthesis of active pharmaceutical ingredients (APIs), essential substances used in drug products to obtain therapeutical effects, is a multi-step chemical process consisting in transforming raw starting materials into several intermediates up to obtain the final molecule.

Each step may represent a manufacturing process requiring multiple units and the need, especially for HPAPIs (highly potent active pharmaceutical ingredients), to use containment equipment to ensure process quality and safety.

To fully support our customers, we provide a full range of modular turnkey systems for different processes and operation units:

A single specific module or multiple modules can be provided based on the project’s complexity.

Overview

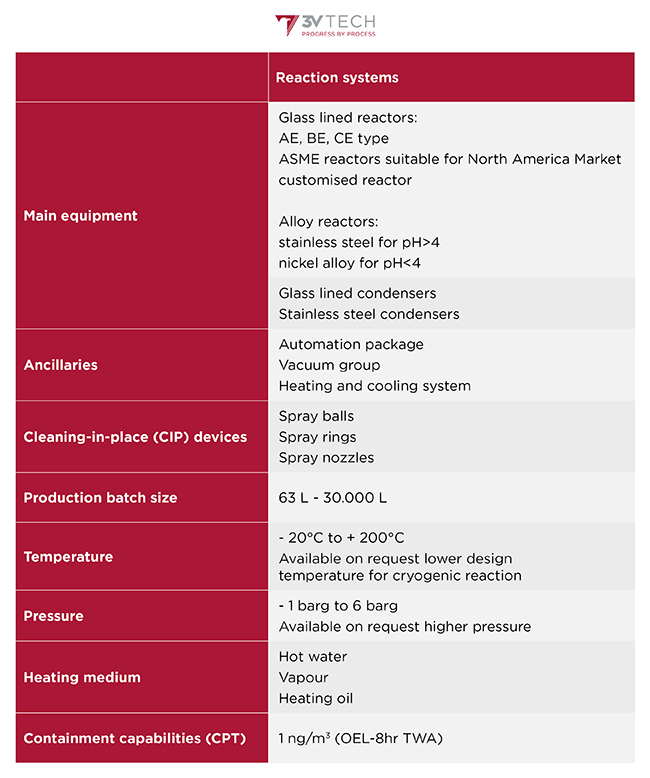

Show more Show lessOur reaction systems normally include the following:

- Reactor

- Vapour line

- Condenser

- Collection vessel for solvent recovery or refluxing line

- Interconnection piping

- Instrumentation

- Supporting structure

- Walking platform and access ladders

The following ancillary equipment is provided on request:

- Automation package

- Vacuum group

- Heating and cooling system

Features and rangeability

Show more Show lessCustomised systems are supplied according to the customer’s needs and expectation. Typical features are reported below.

Should a customer so request, systems can be provided that comply with (or that don’t comply with) the following industry standards:

- GMP

- ATEX

- Processing in an aseptic environment for the production of sterile drugs

In addition to plant systems and equipment, we also provide a wide range of services, from technical feasibility studies to installation and start-up and, cognizant of the attention pharmaceutical industries have for the environment, we also develop and supply solutions to treat wastewater and improve discharge quality.

Key benefits

Show more Show less- More efficient project management thanks to less suppliers

- Decreased project costs and schedule time

- Fully integrated services from process design to construction, installation and start-up

- Customised design

- High automation level

- Remote assistance

Applications

Show more Show lessModular systems can be provided for the production of different kinds of intermediates, APIs and HPAPIs used for oral solid dosage as well as for injectables, parenteral formulations (sterile) and diverse reactions, including cryogenic ones.

Process parameters and equipment need to be specifically identified for each application also to minimise development times and costs and to support process scale-up. At present, we conduct laboratory and pilot testing for filtration and drying.

Our R&D centre will soon be equipped with glass lined reactors to provide comprehensive support to our customers.

References