Plants

Wiped film evaporation or thin film evaporation

Wiped film evaporator or thin film evaporator plants can be effectively used for multiple applications in wastewater treatment: to produce clean water for reuse or recycling, based on the minimum or zero liquid discharge (MLD, ZLD) approach; to concentrate wastewater prior to off-site disposal reducing its volumes and costs; to produce, if necessary, a dry solid waste.

The following streams are separated using evaporation:

- A condensate, free of salts, metals, high boiling point organics, that in most cases can be reused or recycled

- A concentrate for off-site disposal or recovery

Wiped film evaporators (WFE) or thin film evaporators (TFE) and wiped film dryers (WFD) are optimally suited to handle very high viscous and fouling streams: a very challenging or even impossible task for other types of heat exchangers. As a consequence, they are often used in the final stage of ZLD and MLD wastewater treatment plants.

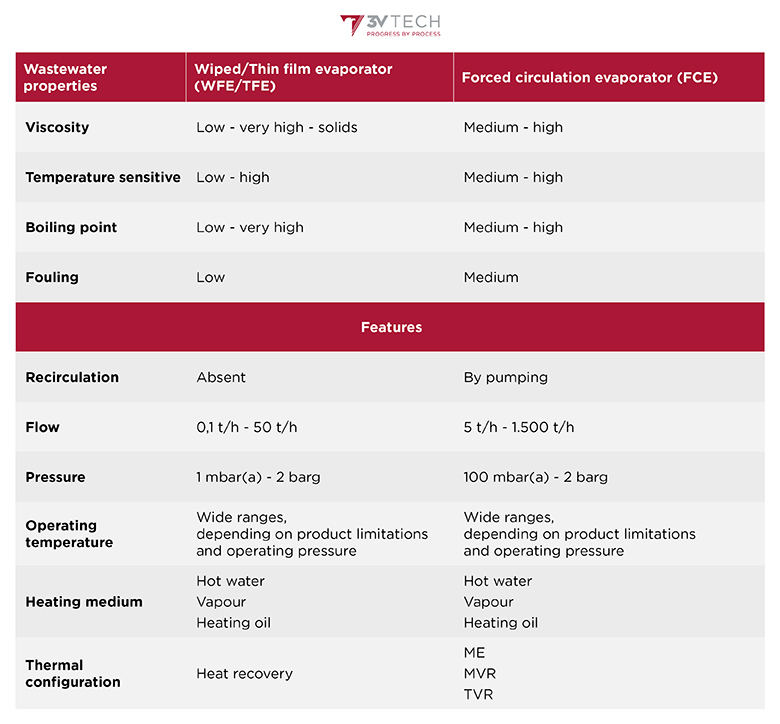

Combining natural circulation or forced circulation evaporators, used in prior concentration stages, provides the best balance in terms of investment, operating costs and performances, especially when a solid waste is required.

More about our natural and forced circulation evaporation plants

Different configurations are possible to optimise energy consumption, such as:

- Using hot water from cogeneration

- Using waste energy (e.g., exhaust gas, steam condensate, process condensate)

- Combining the abovementioned technologies

Overview

Show more Show lessWiped film evaporator (WFE) or thin film evaporator (TFE)

Vertical evaporators consist of:

- A cylindrical, heated, vertical vessel

- A high-speed rotor that maintains a film of product against the wall, in highly turbulent conditions

- A distributor mounted in front of the inlet of the product

- A dynamic droplet separator

The stream to be treated is continuously fed into the evaporator above the heating section and is spread by the distribution ring on the periphery, then collected by the rotor to form a film on the heated surface.

The heat duty is transferred by the heating medium (e.g., hot water, live steam or heating oil) on the external heating side of the cylindrical section of the evaporator (either by means of a jacket or a half pipe).

The configuration of the wiped film evaporator or thin film evaporator permits elevated turbulence of the liquid over the heated surface, improving the heat exchange and keeping the liquid layer thickness at a minimum even at high viscosities.

Various rotor blade designs are possible, according to the specific application. Specifically, for wastewater treatment and especially for ZLD plants, contacting type scraping blades is the standard configuration.

Wiped film evaporator (WFE) or thin film evaporator (TFE) plants

A wiped film evaporation or thin film evaporation plant is typically composed of:

- The evaporator

- A condenser to condense the produced vapour (condensate)

- A condensate discharge pump and a vessel to collect the condensate

- A concentrate discharge pump

For ZLD plants, the following units are also included:

- A dedicated solid discharge system at the bottom of the evaporator to promote the concentrate discharge

- A scrubber to remove any contaminants (e.g., brine salt droplets) entrained by the vapour

A vacuum group is provided when a vacuum is needed to carry out the process, such as for streams having a very high boiling point (e.g., high salt concentration wastewater).

Whenever extreme drying performances are requested, a horizontal thin film high speed rotary dryer (HSRD) can be added to the process.

In this unit, a non-contacting rotor operated at high speed (high Froude number) allows for high production rates and fine tuning the residence time and the final humidity.

Features and rangeability

Show more Show lessWiped film evaporation or thin film evaporation plants are customised according to the customer’s needs and expectations. Typical features are reported below.

Also supplied as skid mounted units to minimise installation operations at the customer’s site.

The most suitable material is selected depending on the nature of the wastewater and operating conditions.

The main materials usually selected for wastewater treatment plants are the following:

- Stainless steel

- Super duplex stainless steel

- Titanium alloys

- Nickel alloys (e.g., Hastelloy® HC22, Inconel® 600)

A wide range of service from technical feasibility studies to revamping existing plants are also available.

Depending on the wastewater composition and end use of the treated water (the condensate), the evaporation plant is coupled with other process technologies to achieve the desired water quality.

Key benefits

Show more Show less- Minimum up to zero liquid discharge

- Water reuse or recycling

- Less wastewater off-site disposal volumes and costs

- Potential recovery of valuable substances

- Customised design

- Combination with other process units

- Bespoke thermal configuration

- High automation level

- Remote assistance

- Easy cleanability

Specific benefits

The specific benefits provided by wiped film evaporators or thin film evaporators are:

- Optimised heat transfer surface, thanks to the high heat transfer coefficient and the possibility to operate with a wide difference in temperature (∆T)

- No fouling problems thanks to the low residence time, high turbulence and continuous cleaning of the heated surface

Applications

Show more Show lessA wide range of applications are possible for both municipal and industrial wastewater, having also a very high content of dissolved solids such as salts, metals or other organic contaminants, and for different wastewater end use:

- Discharge to surface, sewer or other treatment plant

- Reuse/recycling

- Concentration

- Solvent recovery

Wiped film evaporator or thin film evaporator plants address the needs of the following different industries:

- Chemicals

- Food & Beverage

- Landfill

- Mining

- Oil & Gas

- Pharmaceutical

- Power

The wide range of industrial processes generates extensive wastewater compositions to be treated and, whether easy or difficult to treat, each type of wastewater requires a customised process and a bespoke plant design.

We provide support to our customers conducting tests at the laboratory and pilot plant scale as well feasibility studies, leveraging our R&D centre and multi-disciplinary teams.

References