Plants

Essential oils extraction & refining

Essential oils, which are key ingredients for the flavours and fragrances industry, must be processed with particular care due to the high purity levels required for these products and, more importantly, because of their limited thermal stability.

Production becomes even more challenging where non-volatile oils are involved. Extraction from plants using solvents, followed by concentration and purification steps conducted using vacuum evaporation (molecular distillation), are an effective means of obtaining good production rates and avoiding product degradation.

Overview

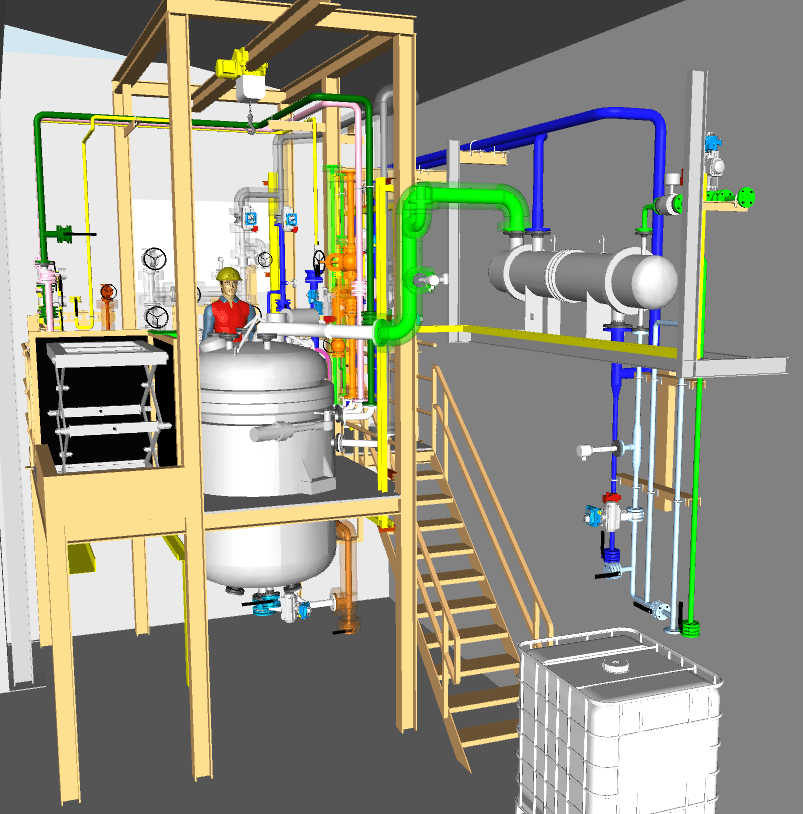

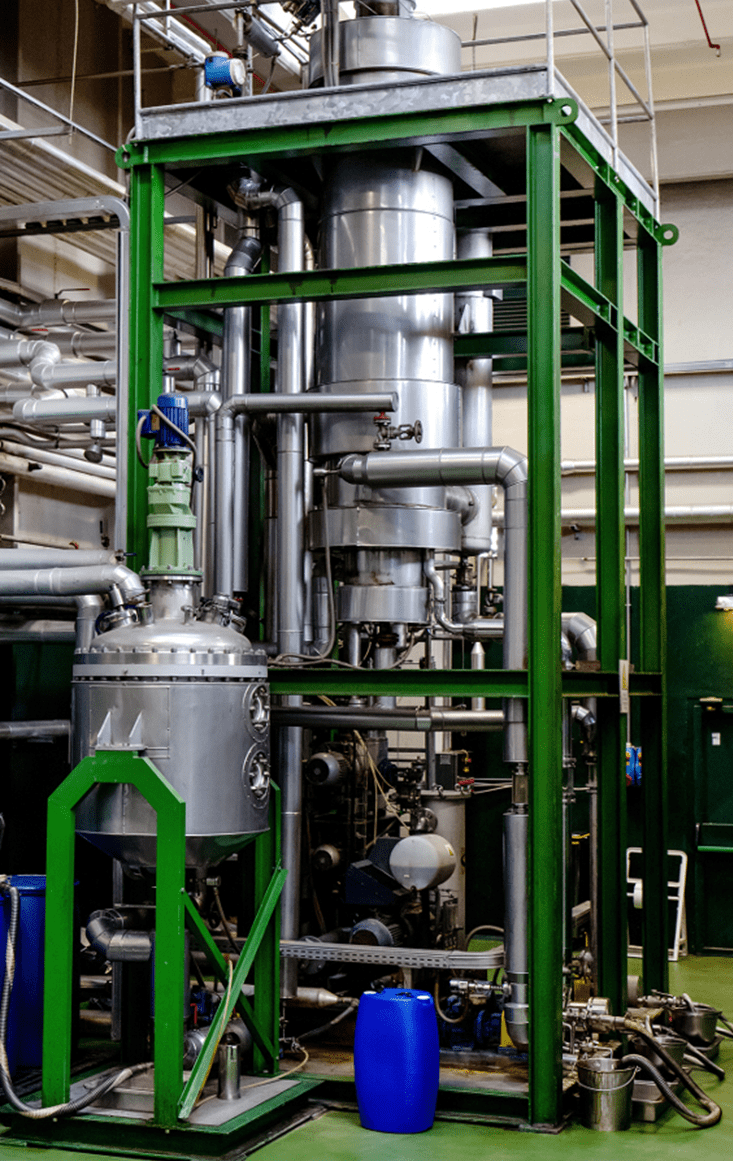

Show more Show lessOur plants can include all the processing steps, after the raw material handling and treatment stages, to obtain the correct feed for the extraction and purification steps, in addition to the solvent recovery unit, designed to reduce operating costs and to process waste.

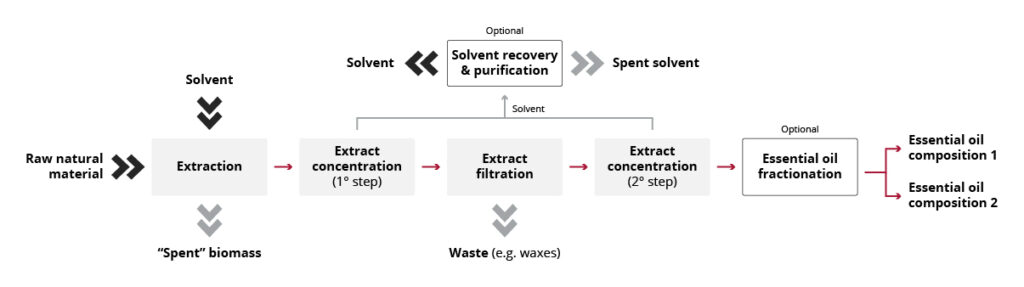

Typical plant configuration for extraction, concentration and purification of essential oils:

- Solvent extraction: key unit operations for this step use agitated Nutsche filter dryers or static extraction vessels.

The extract containing the essential oil and a mixture of other compounds (waxes, residual solids, impurities) is fed during the concentration stage.

Spent biomass, before being disposed of, passes through a drying or steam stripping step to remove all residual traces of solvent, thus reducing solvent consumption and allowing for easier handling of the solid fraction. - Extract concentration: the key processing unit of this section is an evaporator that, based on the extract quality and vegetable extract characteristics, can be a falling film evaporator, a thin film evaporator or a conical batch evaporator.

- Extract filtration: the scope of this section is to remove waxes, residual solids and impurities from the extract.

This stage usually consists of chemical addition and filtration using press filters or basket filters. - Final extract concentration: performed to completely remove the solvent from the natural extract, typically done using agitated thin film evaporators or conical batch evaporators.

- Essential oil purification or fractionation: a potential final step to separate a fraction having a specific composition from the rest of the organic mixture.

The typical processing unit in this case is a short path evaporator that permits a delicate purification avoiding product thermal degradation thanks to short residence time, low operating pressure and low evaporating temperature. - Solvent recovery and purification: solvent recovered in the different process steps can be purified with distillation equipment (batch distillation or continuous distillation). The solvent recovered is re-used in the extraction stage.

To maintain a low temperature and avoid oil decomposition, all operations are performed under vacuum conditions using a vacuum group.

Features and rangeability

Show more Show lessPlants configuration

Specifically designed to provide the necessary evaporation capacity while achieving the desired product composition. Cleaning-in-place (CIP) is implemented in the design to allow rapid and thorough cleaning.

Energy consumption may be optimised by:

- Using hot water from cogeneration

- Using waste energy (e.g., steam condensate, process condensate)

- Combining the abovementioned technologies

Typical production capacity

From 0,1 t/h up to 4 t/h.

Scope of supply

From single main units to the full package.

Typical main piping and equipment materials

Stainless steel (304 or 316).

A wide range of services from technical feasibility studies to revamping existing plants is also feasible.

Key benefits

Show more Show less- No product thermal degradation

- Customised design

- Optimised energy saving

- High automation level

- Remote assistance

Applications

Show more Show lessProduction of essential oils from many different plants or parts of plants (roots, leaves, herbs, grass and flowers) and especially for essential oils that contain thermosensitive natural components.

Depending on the specific properties of the product and the target sought, each step of the process needs to be carefully identified using thermodynamic calculations, simulations and testing, all of which are conducted at our R&D centre, leveraging our multidisciplinary teams.

References