Plants

Falling film evaporation

Falling film evaporation plants are mainly used for limited wastewater concentration and are generally coupled with forced circulation evaporators prior to discharge, reuse or recycling.

More about natural & forced circulation evaporation

The following streams are separated with evaporation:

- A condensate, free of salts, metals and high boiling point contaminants, that in most cases can be reused or recycled

- A concentrate for further treatment, off-site disposal or recovery

Falling film evaporation is suitable for: wastewater containing dissolved salts and minimal suspended solids; low-medium viscous fluids.

Energy consumption may be optimised by:

- Multiple effect evaporation (ME)

- Thermal vapour recompression (TVR)

- Mechanical vapour recompression (MVR)

- Using hot water from cogeneration

- Using waste energy (e.g., exhaust gas, steam condensate, process condensate)

- Combining the abovementioned technologies

Overview

Show more Show lessFalling film evaporators (FFE)

A falling film evaporator is a vertical evaporator consisting of a liquid distribution section at the top, a shell & tube calandria in the middle and a vapour-liquid separation zone at the bottom.

The process fluid flows downwards through the tubes of the calandria by gravity in a co-current flow with the vapour phase and creates a film along the tube walls, where it is partially evaporated.

Heat duty is transferred by the heating medium (e.g., hot water, live steam or heating oil) in the shell of the evaporator.

The generated liquid or vapour mixture is separated into a dedicated separator (either integral or standalone type) to disengage the vapour phase from the liquid concentrated phase.

Falling film evaporator (FFE) plants

A falling film evaporation plant is typically composed of:

- An evaporator

- A separator to separate the produced vapour/liquid mixture

- A circulation pump to maintain the required wettability of the tubes and to transfer the separated concentrated stream

- A condenser to condense the vaporized fraction

- A condensate collection vessel and a pump

When vacuum pressure is needed due to product and/or process requirements, a vacuum group is required.

To recover energy, the feed can be pre-heated by the produced process condensate and/or the heating medium return stream.

Multiple effect (ME) falling film evaporation plants

Multiple effect falling film evaporation plants usually consist in a series of evaporators operating at progressively lower pressure to allow the vapour generated in the upstream effect to be used as the heating medium of the next effect.

The type of evaporator is selected according to the specific application and the solid content in the effluent.

Live steam or another heating medium (e.g., hot water, heating oil) is required for the first evaporation step only.

Vapour from the final effect is condensed by cooling water.

The number of effects is limited by the material corrosion and boiling point elevation (BPE) of the concentrated stream. For condensate or concentrate recovery, thermal degradation can also be a relevant aspect to consider.

In our evaporation plants, the heating process vapour flow and the concentrating product flow arrangements can be a co-current flow, counter flow or only partially in counter flow, depending on the product’s thermal limitations (e.g., thermal sensitivity).

Features and rangeability

Show more Show lessFalling film evaporation plants are customised based on the customer’s needs and expectations.

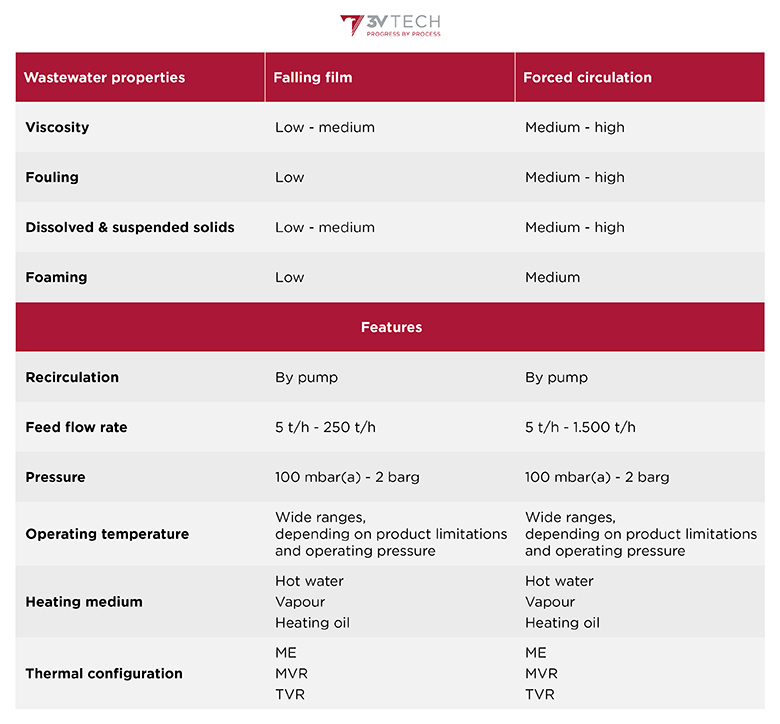

Typical features are shown below, together with a comparison with forced circulation evaporators (FCE) with which the FFE can be combined.

Also available as skid mounted units to minimise installation operations at the customer’s site.

The most suitable material is selected depending on the nature of the process stream and wastewater and the operating conditions.

The main materials usually selected for wastewater treatment plants are the following:

- Stainless steel

- Super duplex stainless steel

- Nickel alloys (e.g., Hastelloy® HC22, Inconel® 600)

- Titanium alloys

A wide range of service from technical feasibility studies to revamping of existing plants are also available.

Depending on the wastewater composition and end use of the treated water (the condensate), the evaporation plant is coupled with other process technologies to achieve the desired water quality.

Key benefits

Show more Show less- Less wastewater off-site disposal volumes and costs

- Potential recovery of valuable substances

- Customised design

- Combination with other technologies and/or process units

- Optimised energy consumption

- High automation level

- Remote assistance

- Easy cleanability

The above benefits are further increased in our unique “multiple effect falling film evaporation” arrangement, providing maximum energy savings, thanks to:

- Using the vapour generated in the upstream effect as the heating medium of the subsequent effect

- Condensate heat recovery

Applications

Show more Show lessA wide range of applications, in combination or not with forced circulation evaporators, are possible for both municipal and industrial wastewater whenever viscosity and content of suspended solids and dissolved salts are low:

- Wastewater treatment prior to discharge to the surface, sewer or other treatment plant

- Wastewater reuse and/or recycling (MLD/ZLD)

- Limited concentration

- Solvent recovery

The falling film evaporator meets the needs of the different industries listed below:

- Chemicals

- Food & beverage

- Landfill

- Mining

- Oil & Gas

- Pharmaceutical

- Power

A wide range of industrial processes generates extensive wastewater compositions and, whether easy or difficult to treat, each type of wastewater requires customised processes and a bespoke plant design.

We provide support to our customers conducting tests at the laboratory and pilot plant scale, as well feasibility studies, leveraging our R&D centre and multi-disciplinary teams.

References