Waste recovery

A growing population and a continually expanding industrial sector have increased waste generation, thus progressively creating an environmental issue. Waste management should therefore improve the efficient use of resources and value waste as a resource in itself.

At 3V Tech, we contribute to this goal by developing process solutions for liquid waste recovery from different industries, including hazardous waste such as waste oils, spent solvents and spent acids.

Waste oil recovery

Re-refining waste lubricant oils to a base oil, mainly used for automotive and industrial applications, is considered to be the best practice, specifically in consideration of a circular economy and waste hierarchy.

Different processes may be used depending on the oil’s origin, application, aging and contamination. The overall treatment mainly consists of dehydration, diesel oil separation and final refining (fractioning and polishing).

We provide the core steps of the process using the following thermal separation technologies:

- Evaporation

- Distillation

These may be combined with other technologies if required.

Solvent recovery

Spent solvents constitute a significant share of hazardous waste and, therefore, recycling them is critically relevant for the industrial user, not only from an environmental viewpoint but also from an economic perspective.

Depending on the nature of the solvents and the intended second use after recycling, we identify the best process solution with thermal separation technologies at its core:

- Evaporation

- Distillation

- Stripping by air, vapour or inert gas

Applications

Show more Show lessRe-refining waste lubricant oils to base oil

Spent solvent recovery

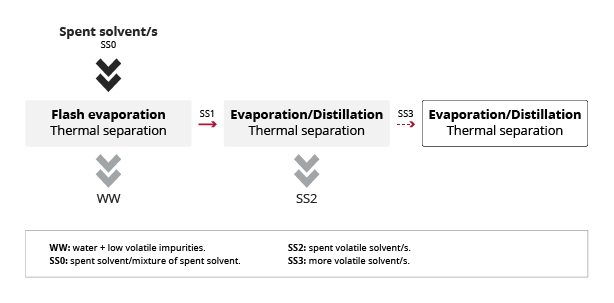

The process may consist of several stages, depending on the nature of the solvent(s), the presence or not of water and other impurities. When more solvents are in the waste stream, then the process steps will increase.

Spent solvent recovery

Mixture of water and solvents to be recovered by the solvent recycling industry or, on-site at the industry premises.

Solvent recovery from wastewater

Solvents often present in industrial wastewater may be recovered in-house from the waste stream, generating a relevant economic value for the industrial user.

Wastewater stream – pharmaceutical industry

Containing suspended solids and dissolved solids (mainly different kinds of organics, including a valuable solvent).

Services

Show more Show lessThe broad range of industrial processes create varied waste compositions and each type of waste requires a custom process and a bespoke plant design.

To identify the proper process steps and to verify process efficacy for a specific type of waste including the final result to be achieved, we run analyses and tests at our R&D centre. In all process development stages, from testing to engineering and plant design, a dedicated team of scientists and engineers assist and support our customers, working together one step at a time.