Sludge treatment

A growing population and a continually expanding industrial sector have increased the annual volumes of treated water making sludge management an increasingly important concern.

Sludge is, in fact, the main waste stream generated by water treatment.

Reducing its volume, the presence of harmful substances, odour and microorganisms potentially dangerous to people’s health and to the environment are fundamental.

As a response to these concerns, years ago we began to develop hydrothermal processes based on wet oxidation to treat sludge coming from the wastewater treatment plant at our own industrial facilities.

We have now placed our extensive experience at the service of industries and municipalities.

Our process solutions

The hydrothermal process, operated at high temperatures and pressures, with air or oxygen, destroys sludge, achieving multiple goals in one step:

- Up to 80% to 90% reduced sludge mass

- Increased sludge settleability and dewaterability

- Up to 96% to 98% oxidation of suspended organic (volatile) solids

- Up to 70% COD removal

- Removal of harmful and bio refractory organic pollutants

- Removal of microbes

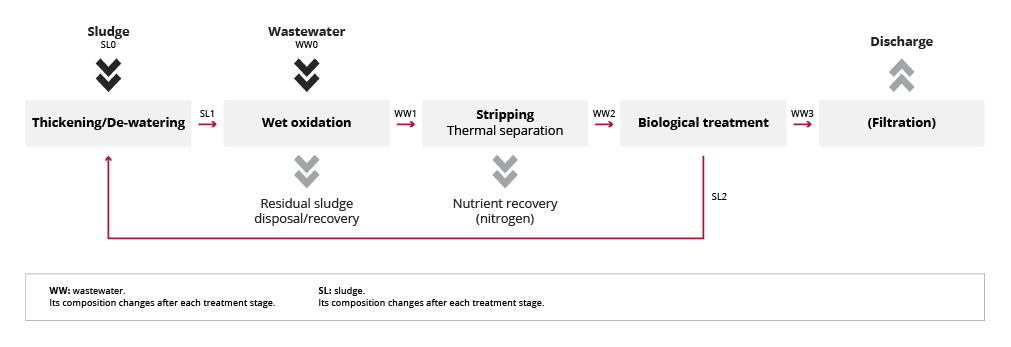

The overall process solution includes other treatments, such as thickening, dewatering and biological oxidation. Sludge is thickened before undergoing a wet oxidation treatment and the water contained in it, with an overall lower content of dissolved organic compounds and rich in biodegradable compounds, can be easily polished through biological treatment.

We also offer a unique process to simultaneously treat sludge and wastewater, leveraging our patented Dual TOP® technology.

Applications

Show more Show lessBiological sludge treatment

Different kinds of biological sludge, originating from urban or industrial wastewater treatment plants, can be treated by changing process operating conditions.

Municipal or industrial sludge

Containing suspended solids and dissolved solids (mainly organics, including refractory pollutants).

Biological sludge treatment & nutrients recovery

Both urban or industrial sludge may contain a relevant quantity of organic nitrogen that can be converted into ammonia by wet oxidation and then recovered by stripping.

Municipal or industrial sludge

Containing suspended solids and dissolved solids (mainly organics, including refractory pollutants).

Biological sludge and wastewater treatment

Different kinds of biological sludge and wastewater, urban or industrial, can be treated by changing process operating conditions.

Services

Show more Show lessThe broad range of industrial processes make broad sludge and wastewater compositions and each composition requires a customised process and a bespoke plant design. To verify process efficacy on the specific sludge or wastewater, we provide support to our customers by performing analyses and tests run at our R&D centre.

In all process development stages, from testing to engineering and plant design, a dedicated team of scientists and engineers assist and support our customers, working together one step at a time.

To fully support our customers that need to treat wastewater without investing in a treatment plant, we offer wastewater collection and outside treatment services operated by our sister company 3V Green Eagle.