Plants

Wet oxidation for biological sludge

Wet oxidation (WO) is a strongly effective hydrothermal process to reduce sludge mass, as well as the presence of harmful substances, COD, odour and microorganisms potentially dangerous to people’s health and to the environment.

It is typically used to treat biological sludge (secondary), originating from the treatment of urban wastewater (sewage sludge) or industrial wastewater.

WO consists in the oxidation of dissolved and suspended pollutants, including refractory ones, at elevated temperatures and pressures using oxygen or air as the oxidizing agent.

The elevated operating pressure maintains water in the liquid phase and improves the oxidation rate by increasing dissolved oxygen concentration. Pollutants are effectively converted into carbon dioxide, water, and intermediate oxidation products (smaller molecules).

The volatile (organic) suspended solids are almost completely removed with up to 80%-90% less sludge mass. The remaining solid, mainly inorganic, can be easily settled and dewatered. Consequently, this results in a noticeable reduction of sludge disposal costs.

The liquid stream is detoxified, odour and colour are almost completely removed and its COD content is strongly decreased. The remaining COD is mostly represented by highly biodegradable, low molecular weight compounds that can be treated in standard WWTP.

Moreover, organic nitrogen is converted into ammonia that can be recovered as a nutrient.

Catalytic wet oxidation may also be employed to achieve greater destruction, operating at lower temperatures and pressures or reduced oxidation time. The aqueous stream is mixed with a catalyst before undergoing the oxidation process.

Overview

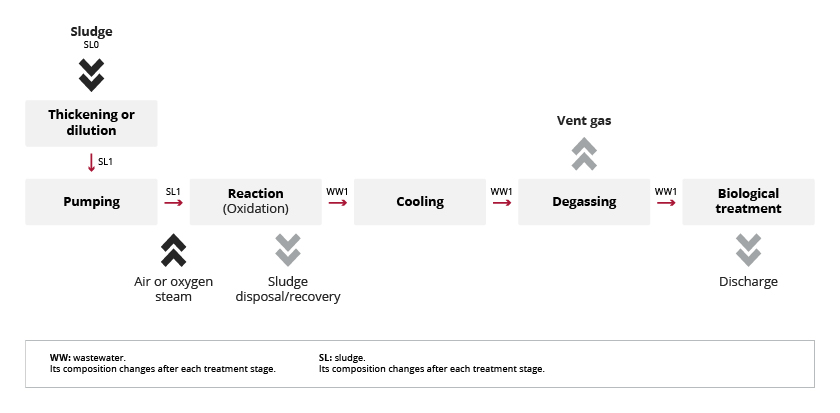

Show more Show lessA WO plant mainly consists of the following sections.

- Sludge is thickened or diluted to achieve the proper COD and solid content and routed to the feeding tank.

- From the feeding tank the sludge stream is sent to the WO plant with pumps, increasing the stream pressure up to the reactor operating pressure.

- In the reactor, the slurry is mixed with the oxidizing agent (air or oxygen) and the high-pressure steam needed to reach the proper operating temperature.

- Heat from the reaction is partially recovered through the steam generated during the depressurization steps, reducing significantly the required energy input.

- Process off-gases from the separator are usually routed to further treatments (e.g., thermal oxidizer, biofilter, biological plant).

- The residual solid present in the final effluent is separated by a static decanter and a centrifuge; the liquid effluent, highly biodegradable, is polished by biological treatment.

Features and rangeability

Show more Show lessWe customise the size of the WO plants according to the type of waste to be treated and to the customer’s performance expectations. Plants are typically operated within the following ranges:

- Feed flow rate: 1 m3/h to 20 m3/h

- Treated biological sludge per year: 600 tons to 13.000 tons as dry sludge

The most suitable material is selected depending on the operating conditions.

The main materials usually selected are the following:

- Stainless steel

- High performances alloys

WO plants are supplied as pre-fabricated modules (skid mounted units), thus minimising the installation operations to be performed at the customer’s site.

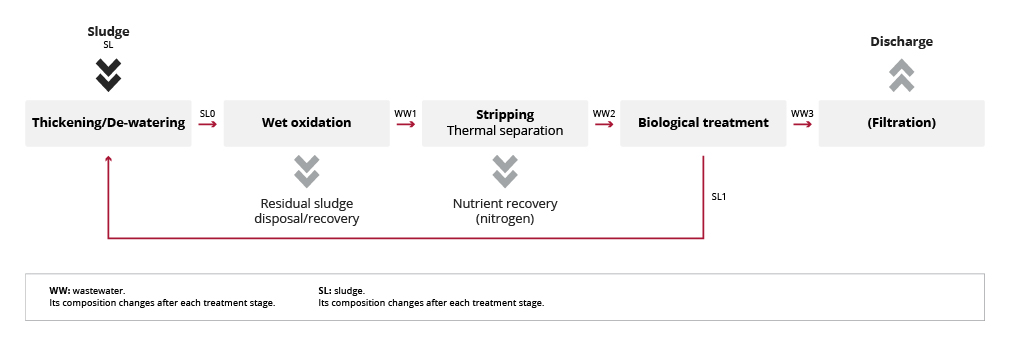

Wet oxidation plants are typically coupled with biological treatment for effluent polishing and can be integrated with stripping to recover nitrogen as a nutrient.

Key benefits

Show more Show less- Relevant savings on sludge disposal costs

- Near complete detoxification of the liquid stream (increased biodegradability)

- Reduced environmental footprint

- Maximum operating flexibility (in feed composition and flowrate)

- Minimum maintenance downtime due to cleaning procedure

- Maximum energy savings

- High automation level

- Reliability

Applications

Show more Show lessTOP technology can be used to treat different kinds of biological sludge originating from urban or industrial wastewater treatment plants and across a wide range of industries:

- Chemical

- Petrochemical

- Pharmaceutical

- Pulp and Paper

- Tanning

- Textile

Multiple goals are achieved in one step:

- Up to 80% to 90% sludge mass reduction

- Up to 96% to 98% oxidation of suspended organic (volatile) solids

- Up to 70% COD removal

- Increased sludge settleability and dewaterability

- Removal of harmful and bio-refractory organic pollutants

- Removal of microbes

Sludge not generated from biological treatment, such as for example for slurry generated in an alumina refinery plant, can also be treated operating under special process conditions.

When sludge and wastewater have to be treated simultaneously, the Dual TOP Technology is available.

The broad range of industrial processes generate extensive sludge compositions and each composition requires a customised process and a bespoke plant design.

We provide support to our customers conducting tests as well feasibility studies, leveraging our R&D centre and multi-disciplinary teams.

References