Plants

Caustic soda concentration

In the chloralkali industry, caustic soda (sodium hydroxide) concentration, produced by electrolytic diaphragm cells and membrane cells, is a key process stage providing several benefits: less volume to be stored, more efficient way to transport, possibility to convert caustic solutions into flakes.

Concentration, usually up to 50%, is achieved by multiple effect evaporation: the number of stages depends on several factors such as the initial caustic concentration, plant size and energy costs.

Overview

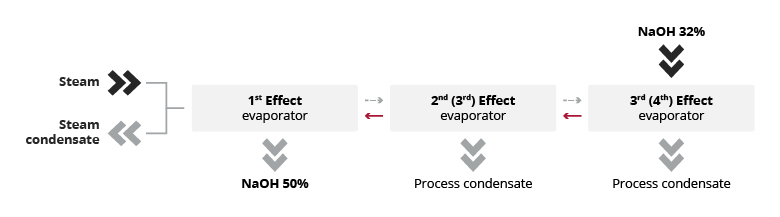

Show more Show lessOur standard solution for concentration from 32 up to 50%, as in the case of caustic soda produced with membrane electrolysis cells, generally requires falling film evaporators in a double or triple effect configuration:

- Evaporators are connected in a series.

- Steam is fed into the first effect, where caustic soda is partially concentrated by water evaporation.

- Process vapour, produced in the first effect, is used as a heating source to promote evaporation in the second effect and, similarly, the process vapour produced in the second effect is used to promote evaporation in the third effect.

- Caustic soda is concentrated in stages to reach the desired final concentration.

- A vacuum group connected to the last evaporator creates the vacuum needed to have a pressure gradient among the stages and to operate at temperatures compatible with the chemical resistance of the material in contact with the highly aggressive environment created by concentrated NaOH.

We carefully optimise plant configurations to achieve the desired performances at the best Capex/Opex ratio.

The number of effects is identified taking into consideration regional energy and steam costs. Where costs are high, additional internal heat recoveries, between hot streams and cold streams, are pursued to further reduce steam consumption.

Features and rangeability

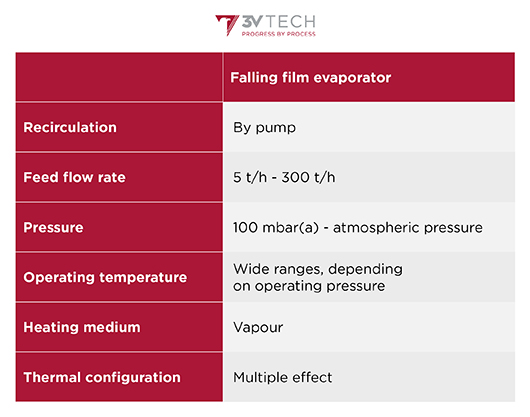

Show more Show lessPlants are customised according to the customer’s needs and expectations; typical features are reported below.

- Also available as skid mounted units to minimise installation operations at the customer’s site.

- Due to the corrosive nature of caustic solutions, nickel or high nickel alloys are typically used as material.

A wide range of services from technical feasibility studies to revamping existing plants is also available on customer request.

Key benefits

Show more Show less- Customised design

- Optimised energy and steam consumption

- High automation level

- Remote assistance

Applications

Show more Show lessConcentration of caustic soda (sodium hydroxide) or potash (potassium hydroxide) solutions, from diaphragm cells and membrane cells, up to 50%.

For higher concentrations, we use dedicated flaking plants.

References